Ngokukhetha ama-monomers athile, umuntu angathola i-polyamide ecwebezelayo futhi esobala unomphela.Amakristalu mancane kangangokuthi awakuhlakazisi ukukhanya okubonakalayo, futhi izinto ezibonakalayo zibonakala sobala emehlweni omuntu—okuyinto eyaziwa ngokuthi i-microcry stallinity.Ngenxa yobucwebe baso, isakhiwo se-microcrystalline sigcina izinto ezibalulekile njengokumelana nokuqhekeka kwengcindezi - ngaphandle kokufiphala.Izinga lokucwebezela alinakwa, kodwa-ke, alinawo umthelela omubi ekuncipheni kokuziphatha kwezingxenye ezibunjiwe.Ithola ukuncipha okufanayo kwe-isotropic njengezinto ezi-amorphous.

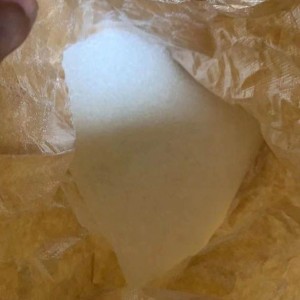

Kuyi-polyamide ene-viscous ephansi, ebonisa ngale unaphakade yokubumba umjovo.